Visual Inspection

A visual inspection is a crucial part of a structural engineering assessment. It involves a

detailed, systematic examination of a structure to identify any visible signs of damage,

deterioration, or other issues that could affect its integrity.

A visual inspection is a crucial part of a structural engineering assessment. It involves a

detailed, systematic examination of a structure to identify any visible signs of damage,

deterioration, or other issues that could affect its integrity.

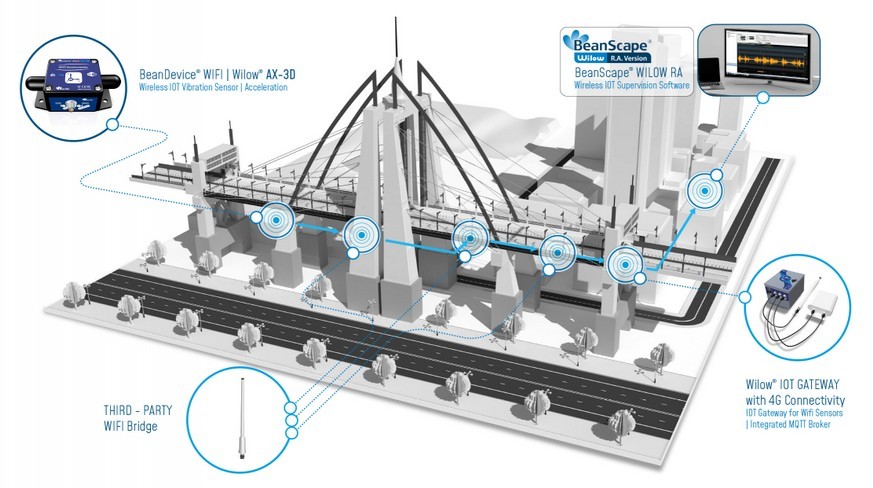

Structural Health Monitoring (SHM)

Structural Health Monitoring (SHM) is an advanced method used to assess the condition of

structures in real-time, providing continuous or periodic data to ensure safety, performance,

and longevity. SHM involves the use of various sensors and data analysis techniques to detect

changes in structural properties that may indicate damage or deterioration.

Structural Health Monitoring (SHM) is an advanced method used to assess the condition of

structures in real-time, providing continuous or periodic data to ensure safety, performance,

and longevity. SHM involves the use of various sensors and data analysis techniques to detect

changes in structural properties that may indicate damage or deterioration.

Non-Destructive Testing (NDT)

Non-Destructive Testing (NDT) refers to a variety of analysis techniques used to evaluate

the properties of a material, component, or system without causing damage. NDT is critical for

ensuring the safety and reliability of structures and components in various industries.

Non-Destructive Testing (NDT) refers to a variety of analysis techniques used to evaluate

the properties of a material, component, or system without causing damage. NDT is critical for

ensuring the safety and reliability of structures and components in various industries.

Coating and Corrosion Inspection

Coating and corrosion inspection is a crucial aspect of maintaining the integrity and

longevity of structures and components, particularly in industries exposed to harsh

environmental conditions, such as marine, oil and gas, and construction. Proper inspection

ensures that protective coatings are effective and that corrosion is detected early, preventing

structural failures and reducing maintenance costs

Coating and corrosion inspection is a crucial aspect of maintaining the integrity and

longevity of structures and components, particularly in industries exposed to harsh

environmental conditions, such as marine, oil and gas, and construction. Proper inspection

ensures that protective coatings are effective and that corrosion is detected early, preventing

structural failures and reducing maintenance costs

Concrete and Masonry Inspection

Concrete and masonry inspection is essential for ensuring the safety, durability, and

performance of structures such as buildings, bridges, dams, and other infrastructure. Proper

inspection identifies defects, monitors the condition, and ensures that construction meets

design specifications and standards.

Concrete and masonry inspection is essential for ensuring the safety, durability, and

performance of structures such as buildings, bridges, dams, and other infrastructure. Proper

inspection identifies defects, monitors the condition, and ensures that construction meets

design specifications and standards.Documentation and Reporting

Documentation and reporting are critical aspects of many professions and industries, ensuring that information is recorded accurately and communicated effectively.